When all the information needed for the plan is defined (stocks, parts, settings), you can start to perform the optimization of cutting layouts.

To start calculation of cutting layouts for the current plan, click the button ![]() in main toolbar. You can also run optimization directly by pressing F3 or by selecting "File > Start optimization" from the menu. You don't have to switch to Results form, the program does it automatically. During the optimization, you can watch its progress and the best results which are achieved.

in main toolbar. You can also run optimization directly by pressing F3 or by selecting "File > Start optimization" from the menu. You don't have to switch to Results form, the program does it automatically. During the optimization, you can watch its progress and the best results which are achieved.

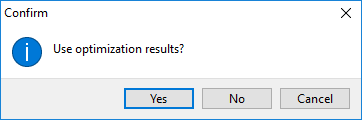

You can stop optimization process at any time by clicking the button ![]() in the main toolbar or by pressing Esc. In such case following confirmation dialog appears.

in the main toolbar or by pressing Esc. In such case following confirmation dialog appears.

If you click the button [Yes], program will stop the optimization and the values will be saved to the plan. Previous results will be overwritten by values which were found in the moment the optimization process was interrupted. If you click the button [No], the optimization will stop and previous results will be left without any change. Values which were found during this last optimization will be ignored. If you click the button [Cancel], the optimization will continue.

When optimization is finished, the best cutting layouts will be automatically entered to the plan. The cutting layouts which were saved the last are always stored for next potential use (additional printing of reports, statistics, etc.).

|

Tip: When you choose particular plan in Plans form and you click the Results tab, you can immediately go over cutting layouts and summary of data which were saved the last. |

|

Tip: If the achieved results fulfill your needs and the optimization is not finished, you can stop it and use these results in the plan. |

Layouts

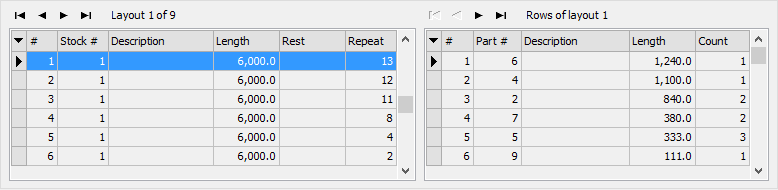

Following data grid shows the cutting layouts which were calculated by the program and user is immediately able to see their overview.

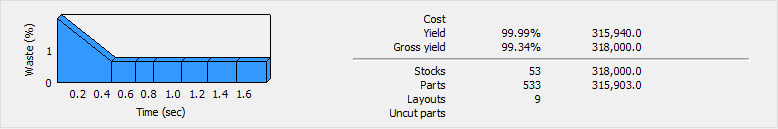

Summary

Here are complete information about the progress of calculation and currently achieved values of an active project (Cost, Yield, Gross yield, Stocks, Parts, Layouts, Uncut parts).

Column 1 |

Column 2 |

Column 3 |

Cost |

- |

Overall cost of the plan. |

Yield |

Achieved utilization in percentage taking into account produced remnants. [Sum length of used parts / (Sum length of used stocks - Sum length of produced remnants)] |

Absolute value of achieved utilization taking into account produced remnants. [Sum length of used stocks - Sum length of produced remnants] |

Gross yield |

Achieved utilization in percentage not taking into account produced remnants. [Sum length of used parts / Sum length of used stocks] |

Absolute value of achieved utilization not taking into account produced remnants. [Sum length of used stocks] |

Stocks |

Number of stocks used in calculated cutting plan. |

[Sum length of used stocks] |

Parts |

Number of parts used in calculated cutting plan. |

[Sum length of used parts] |

Layouts |

Number of layouts of calculated cutting plan. |

- |

Uncut parts |

Number of uncut parts (not used parts) in calculated cutting plan. |

[Sum length of uncut parts] |

Layout

Graphical representation of the layout which is currently selected.

|

Tip: After double click on part or remnant, associated report is printed (e.g. label report). See more in Reports. |